Calendar highlights

(shapeways projections)

(Test Parts ordered)

(Designs finalized)

(Final parts ordered)

(Piece arrives/have piece in hand)

Feb 28th In class work (individual WIP design review/Jumpstart)

March 7th In class work/ Intro 2nd project (review 3D print samples)

March 14th In class work (Demo prongs, talk in depth about settings and stones)

March 21st In class work intro 3rd project (3D scanning demo)

March 28th SPRING BREAK

April 4th Mid term review (Neck it due)

For next class:

Find objects that deliver content in your piece. Use photoshop to mock up. Post images to your blogs. Practice digitize them. Remember scale. It might not need all of the details to get your point across. Practice modeling joints. Send test prints.

For next class:

Find objects that deliver content in your piece. Use photoshop to mock up. Post images to your blogs. Practice digitize them. Remember scale. It might not need all of the details to get your point across. Practice modeling joints. Send test prints.

Basic Review

Project/flow along surface

Objects on a curve

Joint/stirrup

Bin Dixon Ward is a jeweler from Australia that 3D prints all of her work. Her work pushes the tolerance of the 3D printer by making thin interlocking structures that would be nearly impossible to make by hand. She uses SLS 3D printing technology to build the work and then hand dyes all of the pieces. Her work has a playful, whimsical feel being that has a wonderful movement when worn. It is very hard not to play with the work. The is a lot of complex geometry inspired by map data that adds a level of sophistication and comfort to her work.

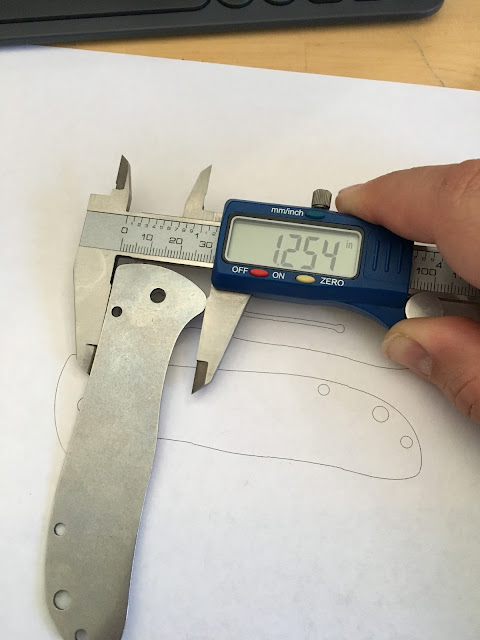

My other parts from a different laser cutter came in the mail yesterday. I am VERY happy with these parts. I used a company called lasergist. Much like Shapeways they are very cheap, provide a great service but have almost non existent customer service. They only laser cut stainless steel. They only cut 304 polished and 316 brushed. They only cut in 1mm, 1.5mm, 2mm or 3mm thicknesses. But....the cutting is fairly cheep. I cut enough parts to make four knives for $168.00 (13 parts with lots of holes). $170.00 is super reasonable considering how beautiful the parts are. As far as knife making, the type of stainless they are using is not very useful. Their website is pretty bare with no indication of where they are located or how long my order would take. Honestly I thought it was fake. I took the gamble and I am very happy I did. Just for the record they are located in Greece. I ordered on Jan 28th and received all of my parts Feb 3rd. If I had one complaint I would argue that the parts are just slightly off. I have not yet slapped on a caliper but some of the small straight cuts seem to be off by a mm or so. Again, it is hard to complain.

No comments:

Post a Comment